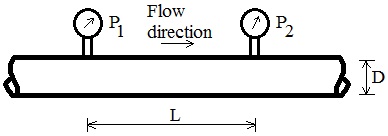

Water Pressure Loss Diagram

Discussion

Understanding pressure loss in pipes helps one design and operate fluid systems. The knowledge of pressure loss is essential for engineers to ensure efficient and effective system performance. The main factors influencing pressure loss include the fluid's viscosity, density, flow rate, diameter, and length. These are the parameters that you can enter in our calculator. This pressure loss calculator computes pressure loss, velocity, Reynolds number, and friction factor for turbulent flow in a horizontal smooth-walled pipe section.

The calculator uses default density and viscosity values for water (density of 1000 kg/m3 and dynamic viscosity of 0.001 N-s/m2), but you can change the values to compute pressure loss for other liquids or gases.

Viscosity is a measure of a fluid's resistance to deformation or flow. Dynamic viscosity is an intrinsic property that significantly impacts how easily a fluid moves through a pipe. Kinematic viscosity is the ratio of dynamic viscosity to fluid density. The user enters dynamic viscosity in our calculator.

Density affects pressure loss by influencing the inertial forces in the fluid. The density of the fluid directly affects the pressure loss. As fluid density increases, the pressure loss increases.

In practical applications, engineers must account for both viscosity and density when designing piping systems. For high-viscosity fluids such as oils and slurries, or for fluids with varying densities such as gases, the impact of these properties on pressure loss becomes more pronounced. For instance, in oil pipelines, increased viscosity leads to significant pressure drops over long distances, requiring more powerful pumps or larger pipe diameters to maintain desired flow rates.

Equations

Pressure loss is calculated for steady flow of an incompressible fluid such as water in a constant diameter horizontal pipe. Using the Darcy-Weisbach friction loss equation, the energy equation for flow from location 1 to 2 is expressed in terms of pressure loss as:

![]()

where:

For pressure loss, the Blasius equation represents the Moody friction factor for smooth pipes and 4000 ≤ Re ≤ 105 (Streeter et al., 1998, p. 291):

![]()

Unit abbreviations, symbols: kg=kilogram, m=meter, N=Newton, s=second. A=Pipe area.

Reference: Streeter, V. L., Wylie, E. B, and Bedford, K. W. 1998. Fluid Mechanics. WCB/McGraw-Hill. 3ed.

© 2017-2026 LMNO Engineering, Research, and Software, Ltd. All rights reserved.

LMNO Engineering, Research, and Software, Ltd.

7860 Angel Ridge Rd. Athens, Ohio 45701 USA Phone: (740) 707-2614

LMNO@LMNOeng.com https://www.LMNOeng.com